SERVICES

We cut for you …

- Construction steel, stainless steel, aluminium, copper

- With flame cutting machines, plasma (Hypertherm 260XD), laser or water

- We work with certified materials only – our EDP enables traceability of test certificates for every single material within seconds

- For forming we have presses and bending machines with max. 6 m length and 600 T power, as well as round rolling machines with max. 30 mm sheet metal thickness on 3,5 m length at disposal.

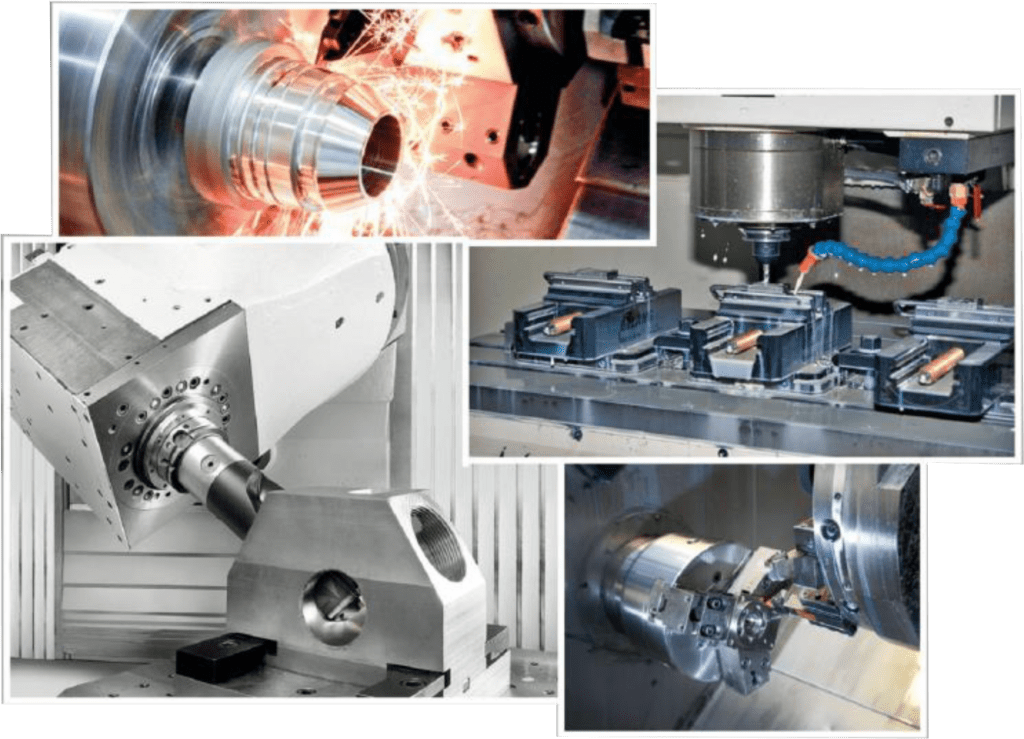

- Our precision mechanics plant integrates CNC turning and milling technologies, 5-axis-machining, circular and surface grinding, rotor balancing, but also many other related technologies.

- Heavy machining being our core competence is performed on several horizontal CNC boring machines and one CNC vertical turret lathe.

- For heat treating we use an annealing furnace up to 700°C

- To achieve the quality we measure μ-accurately – we stand behind our precision with our measurement room equipped with the latest measuring technology and kept in a controlled atmosphere round the clock.

Our certified metalworkers and welders weld for you …

- with MIG-MAG, WIG method

- manually or on robotic welding systems

- our inspectors are VT2-, PT2-, MT2-, UT2-certified

- welding shops are EN ISO 3834-2 und EN 1090-2:2018 certified and supervised by 2 EWE experts

Painting, but environmentally friendly – before applying the final surface coating your parts get sandblasted and carefully prepared in order to gain a high-gloss finish. We give your products exquisite appearance whilst following the latest ecology trends.

In cooperation with our subcontractors we offer you surface treatments such as galvanizing or hardening.